Cable assembly line

Keywords:

requirements

assembly

Category:

Detailed description

1、 Overall concept

Meet the assembly requirements for single and double push pull cables (product and process)

Each workstation adopts manual feeding and manual discharge, and stainless steel trough type suspension chutes are used for alternating transportation between workstations

The production line adopts the principle of single piece flow, with a buffer design of 1-5 pieces between workstations

The production line is designed with a total of 10 workstations (including packaging), each of which is basically balanced. The workstation time rhythm is 20S/set, and the daily output is 1440 sets for 8 hours

For parts that are prone to errors, omissions, and reverse installation, appropriate application of error prevention technology and error prevention monitoring should be carried out

After each process is completed, manual self inspection is conducted on the corresponding assembly characteristics (incorrect or missed installation, whether in place, operational performance, etc.) and corresponding markings are made

Final inspection set up appearance inspection platform: manually reconfirm items such as parts that are prone to errors or omissions, appearance parts, and product performance.

Conduct non-conforming product control, quality management, and process management according to the process

Appropriate application of equipment management, safety, ergonomics, rapid mold and line replacement, appearance and other technologies

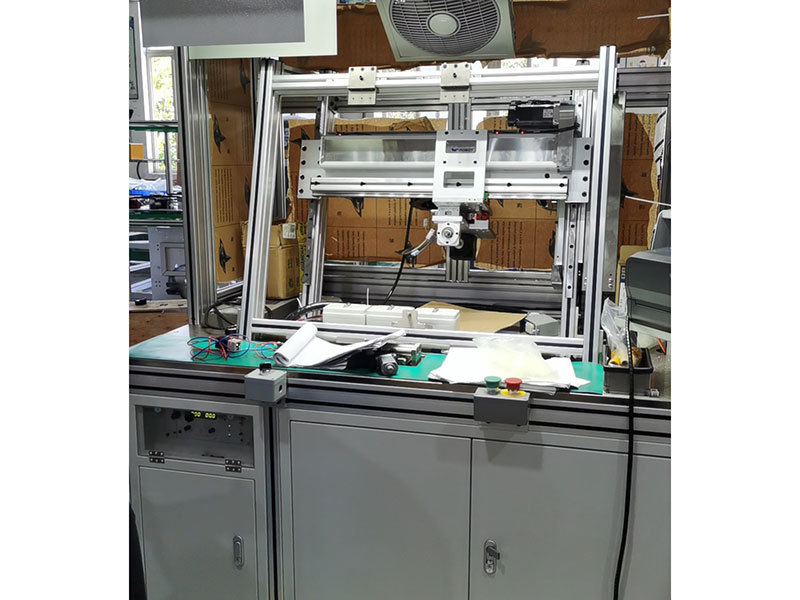

Equipment