Glass regulator production line

Keywords:

Category:

Detailed description

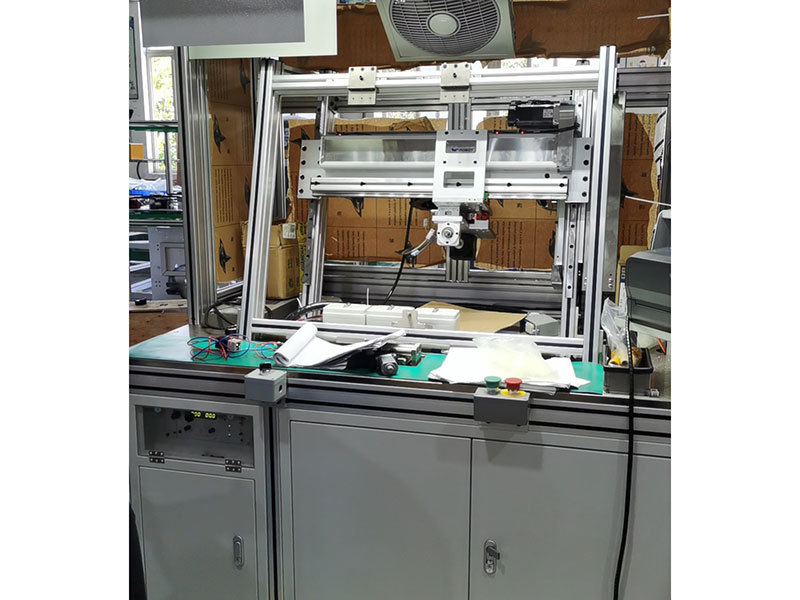

The production line dedicated to the assembly and performance testing of automotive glass regulators is composed of pressure riveting equipment, bolt combination equipment, winding screw equipment, assembly equipment, calibration equipment, etc. Through special equipment, the bolt nut automatic feeding combination is first tightened together, and then 2 cables of different specifications are wound on the reel cylinder and fixed on the cover shell and fixed with screws, and then they are assembled with the guide rail on the final assembly equipment into a complete elevator product, and finally the performance test is carried out on the calibration equipment. The calibration equipment collects data through various detection elements and calculates and compares to judge whether the working current, blocking force, anti-pinch force, ripple performance, factory location, etc. of the elevator product meet the requirements and store the data.

Equipment