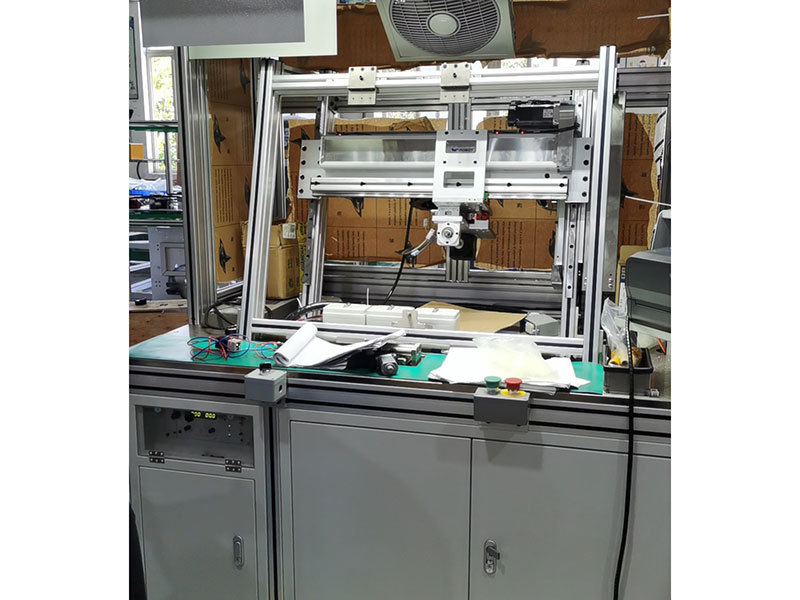

Lasso laser engraving, hot pressing, and pipe cutting integrated machine

Keywords:

Category:

Detailed description

The equipment consists of laser engraving system, hot pressing system, body, conveying device, cutting device, blanking device, safety testing device, grinding wheel cutting device, human-machine interface and programmable controller.

Functions and features of the equipment

1. Drive the product to the size switch position through the conveying device, carry out laser marking and engraving, and cut the product after hot pressing on the surface of the sleeve. After cutting, the blanking device will put the product into the specified position, the counter will be counted once, and the equipment will stop running automatically after repeated operation to the set number of products.

2. The equipment adopts stepper motor to control the pipe feeding speed, with clear marking, good hot-pressing effect, high cutting precision, flat cutting end face, simple operation, high efficiency, stable performance, easy maintenance, long service life, suitable for a variety of types and specifications of the length of the cable sleeve products batch.

Processing range

Product processing diameter: Φ 4 ~ 15 mm

Product processing length: 100 ~ 6000mm

Product processing accuracy: ± 0.5mm

Capacity: 600 or higher

Equipment