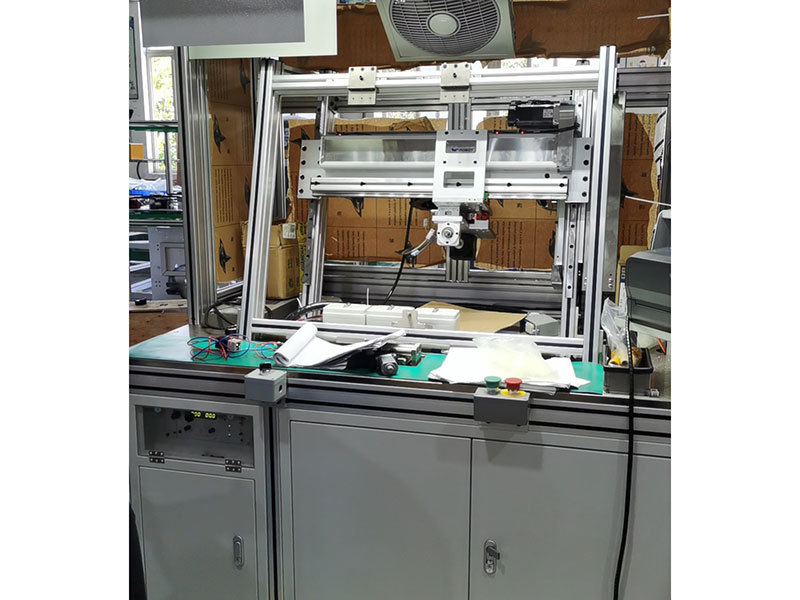

Automatic processing equipment for riveting at both ends of steel wire ropes

Keywords:

Category:

Detailed description

1. Equipment frame: 60*60*5 square pipe steel structure frame, sealing plate, foot cup;

2. Wire rope incoming material sweeping code matching;

3. Wire rope setting mechanism:

4. Spring pulling off mechanism: wire setting, spring pulling, wire pulling, clamping and cutting;

5. Riveting and pressing large chuck mechanism: feed large chuck, parts detection, threading, outcropper detection, gas-liquid booster;

6. Riveting press collet mechanism: feed collet, parts detection, tension, threading, outcroppings detection, gas-liquid supercharging;

7. Pull-off force and dimension detection mechanism: 1080N pull-off force detection, 50N effective length size detection;

8. Sorting mechanism: qualified product box, unqualified product box, batch cache;

9. Print labels for qualified products;

10. Safety cover: aluminum profile frame, safety door, steel wire protection net;

11. Control part: human-machine interface, PLC, battery valve, proximity switch, optical fiber sensor, magnetic switch pressure sensor, displacement sensor, hydraulic relay and other electrical control components;

2.2 Equipment action flow:

1. Material scanning code matching -- 2. Wire rope laying out cache -- 3. Spring piercing -- 4

Reasonable equipment debugging, maintenance door design, better implementation of late equipment debugging and maintenance;

Equipment